The Finest Specialty Prepolymers in the Industry

INTRODUCTION TO PCA CAST ELASTOMERS

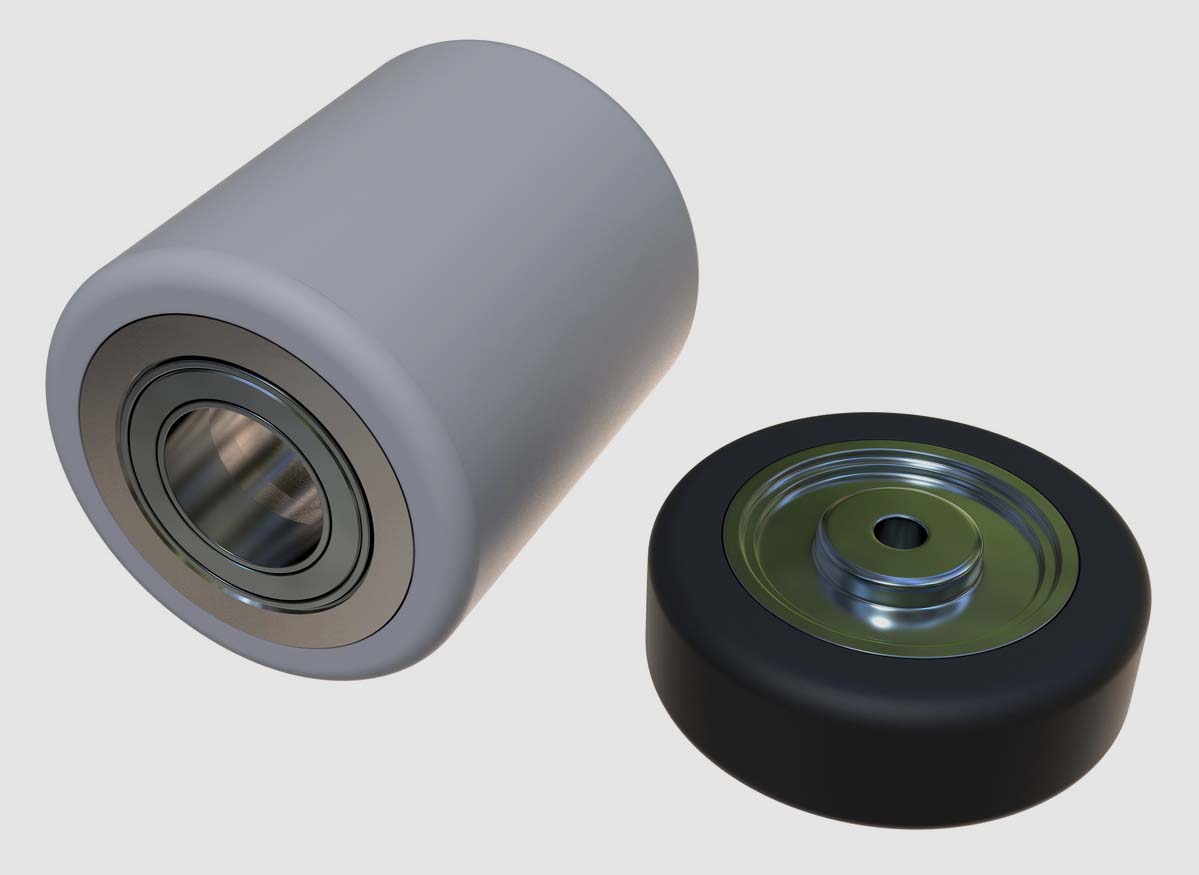

PCA castable urethane elastomers are isocyanate-terminated prepolymers which through chain extension – or as commonly called “curing” – with selected diamines; diol; polyols or other polyfunctional active-hydrogen containing material are converted into high-performance urethane elastomers. By careful selection of the type of PCA prepolymer and the type and ratio of chain extender (“curative”), a wide range of elastomers can be obtained with physical properties tailored to meet specific end application requirements.

When comparing PCA elastomers with many existing plastics, rubber and even metals, a wide range of physical property advantages can be achieved which results in major savings in labor and equipment downtime costs where short service life has been a problem with existing material. These properties, in many cases, include superior toughness and abrasion resistance coupled with excellent dynamic characteristics and resistance to oils, solvents and various other media.

POLYETHER / TDI ELASTOMERS

| Prepolymer Properties | |

| % NCO | 3.3-3.6 |

| Amine Equivalent | 1167-1273 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.9 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 13-15 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-85A |

| Shore Hardness | 83A |

| 100% Modulus, psi | 950 |

| 300% Modulus, psi | 1700 |

| Tensile Strength, psi | 6000 |

| Elongation, % | 500 |

| Tear Strength, DIE C, pli | 530 |

| Tear Strength, D-470, pli | 75 |

| Bashore Resillence, % Rebound | 55 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 20 |

| Prepolymer Properties | |

| % NCO | 3.9-4.3 |

| Amine Equivalent | 975-1075 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 550 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.8 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 5-8 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 55A-90A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1100 |

| 300% Modulus, psi | 2150 |

| Tensile Strength, psi | 5000 |

| Elongation, % | 440 |

| Tear Strength, DIE C, pli | 550 |

| Tear Strength, D-470, pli | 75 |

| Bashore Resillence, % Rebound | 43 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 26 |

| Prepolymer Properties | |

| % NCO | 3.9-4.3 |

| Amine Equivalent | 975-1075 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 550 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.8 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 12-14 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 55A-90A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1100 |

| 300% Modulus, psi | 2150 |

| Tensile Strength, psi | 5000 |

| Elongation, % | 440 |

| Tear Strength, DIE C, pli | 550 |

| Tear Strength, D-470, pli | 75 |

| Bashore Resillence, % Rebound | 43 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 26 |

| Prepolymer Properties | |

| % NCO | 4.0-4.3 |

| Amine Equivalent | 977-1050 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 400 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.9 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 12-14 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-90A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1100 |

| 300% Modulus, psi | 2200 |

| Tensile Strength, psi | 5500 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | 560 |

| Tear Strength, D-470, pli | 80 |

| Bashore Resillence, % Rebound | 50 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 23 |

| Prepolymer Properties | |

| % NCO | 4.8-5.2 |

| Amine Equivalent | 809-875 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 300 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 14.3 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7-9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-92A |

| Shore Hardness | 92A |

| 100% Modulus, psi | 1450 |

| 300% Modulus, psi | 2700 |

| Tensile Strength, psi | 5900 |

| Elongation, % | 430 |

| Tear Strength, DIE C, pli | 550 |

| Tear Strength, D-470, pli | 110 |

| Bashore Resillence, % Rebound | 50 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 25 |

| Prepolymer Properties | |

| % NCO | 6.05-6.55 |

| Amine Equivalent | 640-690 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 150 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 18.1 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 160 |

| Pot Life, Minutes | 6-7 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 95A/48D |

| 100% Modulus, psi | 2200 |

| 300% Modulus, psi | 4400 |

| Tensile Strength, psi | 6800 |

| Elongation, % | 385 |

| Tear Strength, DIE C, pli | 900 |

| Tear Strength, D-470, pli | 130 |

| Bashore Resillence, % Rebound | 40 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 30 |

| Prepolymer Properties | |

| % NCO | 6.05-6.55 |

| Amine Equivalent | 640-690 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 150 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 18.1 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 160 |

| Pot Life, Minutes | 3.-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 95A/48D |

| 100% Modulus, psi | 2200 |

| 300% Modulus, psi | 4400 |

| Tensile Strength, psi | 6800 |

| Elongation, % | 385 |

| Tear Strength, DIE C, pli | 900 |

| Tear Strength, D-470, pli | 130 |

| Bashore Resillence, % Rebound | 40 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 30 |

| Prepolymer Properties | |

| % NCO | 6.2-6.5 |

| Amine Equivalent | 645-675 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 275 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 18.2 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 180 |

| Pot Life, Minutes | 4-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 95A/48D |

| 100% Modulus, psi | 2000 |

| 300% Modulus, psi | 4100 |

| Tensile Strength, psi | 4900 |

| Elongation, % | 320 |

| Tear Strength, DIE C, pli | 500 |

| Tear Strength, D-470, pli | 110 |

| Bashore Resillence, % Rebound | 28 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 30 |

| Prepolymer Properties | |

| % NCO | 7.3-7.8 |

| Amine Equivalent | 535-575 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 300 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 20.3 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 180 |

| Pot Life, Minutes | 3-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-60D |

| Shore Hardness | 60D |

| 100% Modulus, psi | 3000 |

| 300% Modulus, psi | 7000 |

| Tensile Strength, psi | 8000 |

| Elongation, % | 325 |

| Tear Strength, DIE C, pli | 820 |

| Tear Strength, D-470, pli | 125 |

| Bashore Resillence, % Rebound | 47 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 30 |

| Prepolymer Properties | |

| % NCO | 8.4-8.7 |

| Amine Equivalent | 483-500 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 200 |

| Processing Information | |

| Curative | PCA #2⁶ |

| Curative, pph | 23 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 200 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 14-16 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-60D |

| Shore Hardness | 89A |

| 100% Modulus, psi | 600 |

| 300% Modulus, psi | 1100 |

| Tensile Strength, psi | 3600 |

| Elongation, % | 425 |

| Tear Strength, DIE C, pli | 500 |

| Tear Strength, D-470, pli | 100 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 30 |

| Prepolymer Properties | |

| % NCO | 9.5-9.8 |

| Amine Equivalent | 429-442 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 225 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 27.7 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 260 |

| Pot Life, Minutes | 2019-02-03 00:00:00 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-75D |

| Shore Hardness | 75D |

| 100% Modulus, psi | 5200 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 8000 |

| Elongation, % | 220 |

| Tear Strength, DIE C, pli | 1100 |

| Tear Strength, D-470, pli | 130 |

| Bashore Resillence, % Rebound | 45 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 32 |

| Prepolymer Properties | |

| % NCO | 9-5-9.8 |

| Amine Equivalent | 430-445 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 225 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 27.5 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 160 |

| Pot Life, Minutes | 1 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-75D |

| Shore Hardness | 75D |

| 100% Modulus, psi | 5300 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 9000 |

| Elongation, % | 240 |

| Tear Strength, DIE C, pli | 1100 |

| Tear Strength, D-470, pli | 150 |

| Bashore Resillence, % Rebound | 47 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 50 |

¹ Cured 16 hrs. @ 212°F

⁴ May solidify upon prolonged standing or sudden freezing.

⁶ Non-MOCA curative.

GENERAL COMMENTS:

PCA PTMEG-based polyether elastomers are used in applications requiring the high physical properties associated with most polyurethane elastomers with the added features of superior hydrolysis resistance, low-temperature flexibility, fungus resistance and overall improved weatherabiltiy.

PCA 4-2, 5-4, 7-1 and 8-1 are lower cost polyether-based elastomers used in less critical applications where cost is a factor but the general good abrasion properties associated with polyurethane elastomers are still desired.

PCA 7-1 properties are shown above while PCA 4-2,5-4 and 8-1 are available upon request.

POLYESTER / TDI ELASTOMERS

| Prepolymer Properties | |

| % NCO | 3.0-3.3 |

| Amine Equivalent | 1270-1400 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 8-10 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 20A-82A |

| Shore Hardness | 82A |

| 100% Modulus, psi | 900 |

| 300% Modulus, psi | 1200 |

| Tensile Strength, psi | 7700 |

| Elongation, % | 660 |

| Tear Strength, DIE C, pli | 480 |

| Tear Strength, D-470, pli | 110 |

| Bashore Resillence, % Rebound | 40 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 24 |

| Prepolymer Properties | |

| % NCO | 3.0-3.3 |

| Amine Equivalent | 1270-1400 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 5-7 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 20A-82A |

| Shore Hardness | 82A |

| 100% Modulus, psi | 900 |

| 300% Modulus, psi | 1200 |

| Tensile Strength, psi | 7700 |

| Elongation, % | 660 |

| Tear Strength, DIE C, pli | 495 |

| Tear Strength, D-470, pli | 115 |

| Bashore Resillence, % Rebound | 42 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 22 |

| Prepolymer Properties | |

| % NCO | 3.0-3.3 |

| Amine Equivalent | 1270-1400 |

| Appearance @ 77°F/ 25°C | LIQUID³ |

| Typical Visc. @ 212°F/100°C | 1300 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 5-7 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 20A-83A |

| Shore Hardness | 82A |

| 100% Modulus, psi | 550 |

| 300% Modulus, psi | 1100 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 650 |

| Tear Strength, DIE C, pli | 425 |

| Tear Strength, D-470, pli | 105 |

| Bashore Resillence, % Rebound | 25 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 25 |

| Prepolymer Properties | |

| % NCO | 3.7-4.0 |

| Amine Equivalent | 1060-1150 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1050 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 3-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 25A-90A |

| Shore Hardness | 87A |

| 100% Modulus, psi | 920 |

| 300% Modulus, psi | 1800 |

| Tensile Strength, psi | 7500 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 690 |

| Tear Strength, D-470, pli | 125 |

| Bashore Resillence, % Rebound | 33 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 23 |

| Prepolymer Properties | |

| % NCO | 3.55-3.85 |

| Amine Equivalent | 1090-1183 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 950 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 10.8 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 4-6 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-90A |

| Shore Hardness | 88A |

| 100% Modulus, psi | 960 |

| 300% Modulus, psi | 1675 |

| Tensile Strength, psi | 7000 |

| Elongation, % | 575 |

| Tear Strength, DIE C, pli | 695 |

| Tear Strength, D-470, pli | 120 |

| Bashore Resillence, % Rebound | 32 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 22 |

| Prepolymer Properties | |

| % NCO | 3.1-3.5 |

| Amine Equivalent | 1200-1355 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1100 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.4 |

| Stoichiometry, % | 904 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-85A |

| Shore Hardness | 83A |

| 100% Modulus, psi | 700 |

| 300% Modulus, psi | 1300 |

| Tensile Strength, psi | 6800 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 600 |

| Tear Strength, D-470, pli | 115 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 27 |

| Prepolymer Properties | |

| % NCO | 3.3-3.5 |

| Amine Equivalent | 1200-1272 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 2000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 9.7 |

| Stoichiometry, % | 907 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 6-8 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 15A-75A |

| Shore Hardness | 73A |

| 100% Modulus, psi | 330 |

| 300% Modulus, psi | 850 |

| Tensile Strength, psi | 6900 |

| Elongation, % | 515 |

| Tear Strength, DIE C, pli | 320 |

| Tear Strength, D-470, pli | 50 |

| Bashore Resillence, % Rebound | 19 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 17 |

| Prepolymer Properties | |

| % NCO | 3.8-4.1 |

| Amine Equivalent | 1050-1135 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 8-10 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 50A-90A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 900 |

| 300% Modulus, psi | 1800 |

| Tensile Strength, psi | 7500 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 675 |

| Tear Strength, D-470, pli | 120 |

| Bashore Resillence, % Rebound | 32 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 22 |

| Prepolymer Properties | |

| % NCO | 3.8-4.1 |

| Amine Equivalent | 1050-1135 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 3-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 50A-90A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 900 |

| 300% Modulus, psi | 1800 |

| Tensile Strength, psi | 7500 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 690 |

| Tear Strength, D-470, pli | 130 |

| Bashore Resillence, % Rebound | 34 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 20 |

| Prepolymer Properties | |

| % NCO | 4.2-4.5 |

| Amine Equivalent | 935-1000 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 12.5 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 93A |

| 100% Modulus, psi | 1500 |

| 300% Modulus, psi | 3000 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | 720 |

| Tear Strength, D-470, pli | 145 |

| Bashore Resillence, % Rebound | 27 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 27 |

| Prepolymer Properties | |

| % NCO | 3.7-4.0 |

| Amine Equivalent | 1000-1080 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 11.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7-9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-90A |

| Shore Hardness | 86A |

| 100% Modulus, psi | 975 |

| 300% Modulus, psi | 1700 |

| Tensile Strength, psi | 6700 |

| Elongation, % | 560 |

| Tear Strength, DIE C, pli | 645 |

| Tear Strength, D-470, pli | 115 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 22 |

| Prepolymer Properties | |

| % NCO | 5.0-5.3 |

| Amine Equivalent | 2900-3300 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 650 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 14.7 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 5-7 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-50D |

| Shore Hardness | 97A |

| 100% Modulus, psi | 1700 |

| 300% Modulus, psi | 2600 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | 700 |

| Tear Strength, D-470, pli | 180 |

| Bashore Resillence, % Rebound | 24 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 26 |

| Prepolymer Properties | |

| % NCO | 5.0-5.3 |

| Amine Equivalent | 2900-3300 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 650 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 14.7 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-50D |

| Shore Hardness | 97A |

| 100% Modulus, psi | 1700 |

| 300% Modulus, psi | 2600 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | 720 |

| Tear Strength, D-470, pli | 195 |

| Bashore Resillence, % Rebound | 26 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 24 |

| Prepolymer Properties | |

| % NCO | 57.-6.0 |

| Amine Equivalent | 700-737 |

| Appearance @ 77°F/ 25°C | LIQUID³ |

| Typical Visc. @ 212°F/100°C | 900 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 16.7 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-54D |

| Shore Hardness | 54D |

| 100% Modulus, psi | 2000 |

| 300% Modulus, psi | 3100 |

| Tensile Strength, psi | 6900 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | 800 |

| Tear Strength, D-470, pli | 190 |

| Bashore Resillence, % Rebound | 24 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 29 |

| Prepolymer Properties | |

| % NCO | 5.4-5.7 |

| Amine Equivalent | 735-778 |

| Appearance @ 77°F/ 25°C | LIQUID³ |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 15.9 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 70A-50D |

| Shore Hardness | 50D |

| 100% Modulus, psi | 1800 |

| 300% Modulus, psi | 2850 |

| Tensile Strength, psi | 6800 |

| Elongation, % | 460 |

| Tear Strength, DIE C, pli | 720 |

| Tear Strength, D-470, pli | 180 |

| Bashore Resillence, % Rebound | 24 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 28 |

| Prepolymer Properties | |

| % NCO | 6.0-6.3 |

| Amine Equivalent | 667-700 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 500 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 17.50 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 80A-60D |

| Shore Hardness | 60D |

| 100% Modulus, psi | 2500 |

| 300% Modulus, psi | 4750 |

| Tensile Strength, psi | 8500 |

| Elongation, % | 430 |

| Tear Strength, DIE C, pli | 1300 |

| Tear Strength, D-470, pli | 180 |

| Bashore Resillence, % Rebound | 31 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 28 |

| Prepolymer Properties | |

| % NCO | 6.1-6.4 |

| Amine Equivalent | 655-690 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 18.0 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 2-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 80A-60D |

| Shore Hardness | 60D |

| 100% Modulus, psi | 2800 |

| 300% Modulus, psi | 5500 |

| Tensile Strength, psi | 8000 |

| Elongation, % | 405 |

| Tear Strength, DIE C, pli | 1350 |

| Tear Strength, D-470, pli | 190 |

| Bashore Resillence, % Rebound | 39 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 27 |

| Prepolymer Properties | |

| % NCO | 7.2-7.50 |

| Amine Equivalent | 575-600 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 400 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 20.5 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 2-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-80D |

| Shore Hardness | 75D |

| 100% Modulus, psi | 4800 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 9000 |

| Elongation, % | 280 |

| Tear Strength, DIE C, pli | 1700 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 38 |

| Prepolymer Properties | |

| % NCO | 8.0-8.3 |

| Amine Equivalent | 506-525 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 390 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 23.3 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 190 |

| Pot Life, Minutes | 2-3 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-80D |

| Shore Hardness | 80D |

| 100% Modulus, psi | 4850 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 8800 |

| Elongation, % | 290 |

| Tear Strength, DIE C, pli | 1800 |

| Tear Strength, D-470, pli | 165 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 37 |

| Prepolymer Properties | |

| % NCO | 9.5-9.8 |

| Amine Equivalent | 428-442 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 450 |

| Processing Information | |

| Curative | MOCA |

| Curative, pph | 27.6 |

| Stoichiometry, % | 90 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 150 |

| Pot Life, Minutes | 1 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 80A-70D |

| Shore Hardness | 70D |

| 100% Modulus, psi | 4500 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 8400 |

| Elongation, % | 275 |

| Tear Strength, DIE C, pli | 1700 |

| Tear Strength, D-470, pli | 200 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | |

| (Method B 22 hrs, @ 158°F) | 37 |

¹Cured 16 hrs. @ 212°F

²PCA 300, 400, 500, 600 and 700 are slow reacting versions of PCA 301, 401, 501, 601 and 901 respectively. Selection of the type used will depend on the process parameters required such as a longer pot life for pouring larger castings or a faster pot life for shorter demold times.

ᶟThese elastomers are uniquely liquid at room temperature for manufacturing processes not readily adaptable to long melt cycles which are required for solid prepolymers.

POLYESTER / MDI ELASTOMERS

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 |

| Curative, pph | 7.4 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 11-13 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 60A |

| 100% Modulus, psi | 260 |

| 300% Modulus, psi | 600 |

| Tensile Strength, psi | 3800 |

| Elongation, % | 520 |

| Tear Strength, DIE C, pli | 200 |

| Tear Strength, D-470, pli | 60 |

| Bashore Resillence, % Rebound | 20 |

| Compression Set, % | 55⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 6.2/1.6 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 9-11 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 65S |

| 100% Modulus, psi | 440 |

| 300% Modulus, psi | 650 |

| Tensile Strength, psi | 4200 |

| Elongation, % | 525 |

| Tear Strength, DIE C, pli | 220 |

| Tear Strength, D-470, pli | 70 |

| Bashore Resillence, % Rebound | 22 |

| Compression Set, % | 35⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 4.5/3.0 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7-9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 75A |

| 100% Modulus, psi | 630 |

| 300% Modulus, psi | 1350 |

| Tensile Strength, psi | 5500 |

| Elongation, % | 530 |

| Tear Strength, DIE C, pli | 450 |

| Tear Strength, D-470, pli | 105 |

| Bashore Resillence, % Rebound | 25 |

| Compression Set, % | 33⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 6.8 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 4-6 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 85A |

| 100% Modulus, psi | 870 |

| 300% Modulus, psi | 1600 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 620 |

| Tear Strength, DIE C, pli | 600 |

| Tear Strength, D-470, pli | 160 |

| Bashore Resillence, % Rebound | 33 |

| Compression Set, % | 28⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4 BD / HQEE |

| Curative, pph | 3.4/7.2 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1250 |

| 300% Modulus, psi | 2100 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 560 |

| Tear Strength, DIE C, pli | 630 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | 30⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | HQEE |

| Curative, pph | 14.5 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 2-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 95A |

| 100% Modulus, psi | 1650 |

| 300% Modulus, psi | 2670 |

| Tensile Strength, psi | 7000 |

| Elongation, % | 530 |

| Tear Strength, DIE C, pli | 650 |

| Tear Strength, D-470, pli | 180 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | 20⁷ |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | LIQUIDᶟ |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 6.8 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7.9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 84A |

| 100% Modulus, psi | 810 |

| 300% Modulus, psi | 1500 |

| Tensile Strength, psi | 6000 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 580 |

| Tear Strength, D-470, pli | 145 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | 33 |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | LIQUIDᶟ |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | HQEE |

| Curative, pph | 14.5 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 3.-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 94A |

| 100% Modulus, psi | 1590 |

| 300% Modulus, psi | 2550 |

| Tensile Strength, psi | 6000 |

| Elongation, % | 525 |

| Tear Strength, DIE C, pli | 620 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 36 |

| Compression Set, % | 32 |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 8.9-9.4 |

| Amine Equivalent | 445-470 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 500 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 9.3 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 4-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-60D |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1650 |

| 300% Modulus, psi | 3950 |

| Tensile Strength, psi | 7800 |

| Elongation, % | 470 |

| Tear Strength, DIE C, pli | 670 |

| Tear Strength, D-470, pli | 175 |

| Bashore Resillence, % Rebound | 28 |

| Compression Set, % | 32 |

| (Method B 22 hrs, @ 158°F) | |

| Prepolymer Properties | |

| % NCO | 8.9-9.4 |

| Amine Equivalent | 445-470 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 500 |

| Processing Information | |

| Curative | PCA #14 |

| Curative, pph | 19.4 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 240 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 1-2 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 90A-60D |

| Shore Hardness | 60D |

| 100% Modulus, psi | 3300 |

| 300% Modulus, psi | 3500 |

| Tensile Strength, psi | 3600 |

| Elongation, % | 360 |

| Tear Strength, DIE C, pli | 1000 |

| Tear Strength, D-470, pli | 200 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | 36 |

| (Method B 22 hrs, @ 158°F) | |

¹Cured 16 hrs. @ 212°F

ᶟThese elastomers are uniquely liquid at room temperature for manufacturing processes not readily adaptable to long melt cycles which are required for solid prepolymers.

⁷Significantly lower compression set characteristics may be obtained by using a small amount of a multifunctional curative such as TMP.

GENERAL COMMENTS:

PSC 602 AND 603 may be used to comer a Shore A durometer range from 60 A to 95 Shore A by using various diol or polyol non-toxic curatives or curative blends depending on physical property requirements.

Superior physical properties are usually derived from PCA 602. PCA 603 has the advantage of being a liquid at room temperature and does not require a long melt cycle.

Higher durometers up to 70 Shore D may be obtained by using PCA701 and various glycol-based curative blends.

Durometers below 95A may also be obtained with PCA 701 if desired.

POLYETHER / MDI ELASTOMERS

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 |

| Curative, pph | 7.4 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 11-13 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 60A |

| 100% Modulus, psi | 260 |

| 300% Modulus, psi | 600 |

| Tensile Strength, psi | 3800 |

| Elongation, % | 520 |

| Tear Strength, DIE C, pli | 200 |

| Tear Strength, D-470, pli | 60 |

| Bashore Resillence, % Rebound | 20 |

| Compression Set, % | 55⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 6.2/1.6 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 9-11 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 65S |

| 100% Modulus, psi | 440 |

| 300% Modulus, psi | 650 |

| Tensile Strength, psi | 4200 |

| Elongation, % | 525 |

| Tear Strength, DIE C, pli | 220 |

| Tear Strength, D-470, pli | 70 |

| Bashore Resillence, % Rebound | 22 |

| Compression Set, % | 35⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 4.5/3.0 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7-9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 75A |

| 100% Modulus, psi | 630 |

| 300% Modulus, psi | 1350 |

| Tensile Strength, psi | 5500 |

| Elongation, % | 530 |

| Tear Strength, DIE C, pli | 450 |

| Tear Strength, D-470, pli | 105 |

| Bashore Resillence, % Rebound | 25 |

| Compression Set, % | 33⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 6.8 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 4-6 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 85A |

| 100% Modulus, psi | 870 |

| 300% Modulus, psi | 1600 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 620 |

| Tear Strength, DIE C, pli | 600 |

| Tear Strength, D-470, pli | 160 |

| Bashore Resillence, % Rebound | 33 |

| Compression Set, % | 28⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4 BD / HQEE |

| Curative, pph | 3.4/7.2 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1250 |

| 300% Modulus, psi | 2100 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 560 |

| Tear Strength, DIE C, pli | 630 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | 30⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | HQEE |

| Curative, pph | 14.5 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 2-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 95A |

| 100% Modulus, psi | 1650 |

| 300% Modulus, psi | 2670 |

| Tensile Strength, psi | 7000 |

| Elongation, % | 530 |

| Tear Strength, DIE C, pli | 650 |

| Tear Strength, D-470, pli | 180 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | 20⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | LIQUIDᶟ |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 6.8 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7.9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 84A |

| 100% Modulus, psi | 810 |

| 300% Modulus, psi | 1500 |

| Tensile Strength, psi | 6000 |

| Elongation, % | 600 |

| Tear Strength, DIE C, pli | 580 |

| Tear Strength, D-470, pli | 145 |

| Bashore Resillence, % Rebound | 30 |

| Compression Set, % | 33 |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | LIQUIDᶟ |

| Typical Visc. @ 212°F/100°C | 600 |

| Processing Information | |

| Curative | HQEE |

| Curative, pph | 14.5 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 3.-4 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 94A |

| 100% Modulus, psi | 1590 |

| 300% Modulus, psi | 2550 |

| Tensile Strength, psi | 6000 |

| Elongation, % | 525 |

| Tear Strength, DIE C, pli | 620 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 36 |

| Compression Set, % | 32 |

| (Method B 22 hrs, @ 158°F) |

¹Cured 16 hrs. @ 212°F

²PCA 300, 400, 500, 600 and 700 are slow reacting versions of PCA 301, 401, 501, 601 and 901 respectively. Selection of the type used will depend on the process parameters required such as a longer pot life for pouring larger castings or a faster pot life for shorter demold times.

ᶟThese elastomers are uniquely liquid at room temperature for manufacturing processes not readily adaptable to long melt cycles which are required for solid prepolymers.

POLYCAPROLACTONE / MDI ELASTOMERS

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 |

| Curative, pph | 7.4 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 11-13 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 60A |

| 100% Modulus, psi | 260 |

| 300% Modulus, psi | 600 |

| Tensile Strength, psi | 3800 |

| Elongation, % | 520 |

| Tear Strength, DIE C, pli | 200 |

| Tear Strength, D-470, pli | 60 |

| Bashore Resillence, % Rebound | 20 |

| Compression Set, % | 55⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 6.2/1.6 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 9-11 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 65S |

| 100% Modulus, psi | 440 |

| 300% Modulus, psi | 650 |

| Tensile Strength, psi | 4200 |

| Elongation, % | 525 |

| Tear Strength, DIE C, pli | 220 |

| Tear Strength, D-470, pli | 70 |

| Bashore Resillence, % Rebound | 22 |

| Compression Set, % | 35⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | PCA #53 /1,4BD |

| Curative, pph | 4.5/3.0 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 7-9 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 75A |

| 100% Modulus, psi | 630 |

| 300% Modulus, psi | 1350 |

| Tensile Strength, psi | 5500 |

| Elongation, % | 530 |

| Tear Strength, DIE C, pli | 450 |

| Tear Strength, D-470, pli | 105 |

| Bashore Resillence, % Rebound | 25 |

| Compression Set, % | 33⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4BD |

| Curative, pph | 6.8 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 150 |

| Prepolymer, Temp °F | 212 |

| Pot Life, Minutes | 4-6 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 85A |

| 100% Modulus, psi | 870 |

| 300% Modulus, psi | 1600 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 620 |

| Tear Strength, DIE C, pli | 600 |

| Tear Strength, D-470, pli | 160 |

| Bashore Resillence, % Rebound | 33 |

| Compression Set, % | 28⁷ |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 6.4-6.7 |

| Amine Equivalent | 625-655 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 700 |

| Processing Information | |

| Curative | 1,4 BD / HQEE |

| Curative, pph | 3.4/7.2 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 215 |

| Pot Life, Minutes | 3-5 |

| Elastomer Properties¹ | |

| Shore Hardness Range, Attainable | 60A-95A |

| Shore Hardness | 90A |

| 100% Modulus, psi | 1250 |

| 300% Modulus, psi | 2100 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 560 |

| Tear Strength, DIE C, pli | 630 |

| Tear Strength, D-470, pli | 170 |

| Bashore Resillence, % Rebound | 35 |

| Compression Set, % | 30⁷ |

| (Method B 22 hrs, @ 158°F) |

¹Cured 16 hrs. @ 212°F

²PCA 300, 400, 500, 600 and 700 are slow reacting versions of PCA 301, 401, 501, 601 and 901 respectively. Selection of the type used will depend on the process parameters required such as a longer pot life for pouring larger castings or a faster pot life for shorter demold times.

ᶟThese elastomers are uniquely liquid at room temperature for manufacturing processes not readily adaptable to long melt cycles which are required for solid prepolymers.

ALIPHATIC BASED ELASTOMERS

| Prepolymer Properties | |

| % NCO | 4.0-4.3 |

| Amine Equivalent | 977-1050 |

| Appearance @ 77°F/ 25°C | SOLID |

| Typical Visc. @ 212°F/100°C | 1500 |

| Processing Information | |

| Curative | MDA |

| Curative, pph | 9.3 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 5-6 |

| Elastomer Properties¹ | |

| Shore Hardness | 87A |

| 100% Modulus, psi | 900 |

| 300% Modulus, psi | 1750 |

| Tensile Strength, psi | 5400 |

| Elongation, % | 450 |

| Tear Strength, DIE C, pli | - |

| Tear Strength, D-470, pli | 100 |

| Bashore Resillence, % Rebound | 45 |

| Compression Set, % | 35 |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 4.6-4.9 |

| Amine Equivalent | 857-913 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MDA |

| Curative, pph | 10.6 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 4-5 |

| Elastomer Properties¹ | |

| Shore Hardness | 91A |

| 100% Modulus, psi | 1200 |

| 300% Modulus, psi | 3300 |

| Tensile Strength, psi | 5000 |

| Elongation, % | 375 |

| Tear Strength, DIE C, pli | - |

| Tear Strength, D-470, pli | 60 |

| Bashore Resillence, % Rebound | 40 |

| Compression Set, % | 40 |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 5.5-5.8 |

| Amine Equivalent | 724-764 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 1000 |

| Processing Information | |

| Curative | MDA |

| Curative, pph | 12.7 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 2-3 |

| Elastomer Properties¹ | |

| Shore Hardness | 95A |

| 100% Modulus, psi | 1700 |

| 300% Modulus, psi | 4000 |

| Tensile Strength, psi | 6500 |

| Elongation, % | 400 |

| Tear Strength, DIE C, pli | - |

| Tear Strength, D-470, pli | 110 |

| Bashore Resillence, % Rebound | 42 |

| Compression Set, % | 40 |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 7.7-8.0 |

| Amine Equivalent | 525-545 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 900 |

| Processing Information | |

| Curative | MDA |

| Curative, pph | 17.6 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 1-2 |

| Elastomer Properties¹ | |

| Shore Hardness | 58D |

| 100% Modulus, psi | 3200 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 6500 |

| Elongation, % | 260 |

| Tear Strength, DIE C, pli | - |

| Tear Strength, D-470, pli | 100 |

| Bashore Resillence, % Rebound | 42 |

| Compression Set, % | 43 |

| (Method B 22 hrs, @ 158°F) |

| Prepolymer Properties | |

| % NCO | 8.0-8.3 |

| Amine Equivalent | 506-525 |

| Appearance @ 77°F/ 25°C | LIQUID⁴ |

| Typical Visc. @ 212°F/100°C | 850 |

| Processing Information | |

| Curative | MDA |

| Curative, pph | 18.3 |

| Stoichiometry, % | 95 |

| Curative, Temp. °F | 230 |

| Prepolymer, Temp °F | 200 |

| Pot Life, Minutes | 1-2 |

| Elastomer Properties¹ | |

| Shore Hardness | 75D |

| 100% Modulus, psi | 4600 |

| 300% Modulus, psi | - |

| Tensile Strength, psi | 6800 |

| Elongation, % | 180 |

| Tear Strength, DIE C, pli | - |

| Tear Strength, D-470, pli | 100 |

| Bashore Resillence, % Rebound | 42 |

| Compression Set, % | 40 |

| (Method B 22 hrs, @ 158°F) |

¹Cured 16 hrs. @ 212°F

⁴ May solidify upon prolonged standing or sudden freezing.

GENERAL COMMENTS:

PCA aliphatic isocyanate based prepolymers offer several distinct advantages to a polyurethane processor. These are:

A) The elimination of the controversial toxicological properties associated with the commonly used p.p. methylene-bis- (ortho chloroaniline).

B) Light stability not available in TDI and MDI based elastomers. These types of elastomers may be used where discoloration is a problem with standard elastomers.

C) These elastomers have also displayed superior hot water resistance in various applications when compared to most standard polyurethane elastomers.